When maintained well, Genfare fareboxes, vaults, and other hardware can last for decades. To get the longest life and most continuous revenue service from your fare collection hardware, it’s important to stay on schedule with preventive maintenance. While the farebox is just a small part of the bus, it’s vital to collecting operational revenue, so keeping it running should be a priority.

“If agencies are not proactive, they are going to be reactive,” says Michael Horbrook, trainer at Genfare. “If preventive maintenance isn’t done, it will lead to urgent repairs that cost more and take longer. You reap what you sow.”

“Any moving part on a farebox will eventually run into an issue if not maintained,” agrees Freddy Sanchez, trainer at Genfare. “Transit agency mechanics have their hands full, so I understand why prevention often falls behind, but it will save them time and money in the long run.”

Keeping preventive maintenance parts in stock

Transit agencies that put an emphasis on preventive maintenance keep at least 10 percent of components they will need available, preferably in stock. For example, if you have 100 fareboxes, you’ll want to have 10 of each moveable or consumable part that needs regular replacement. Items like cleaning cards, lubricants, compressed air, isopropyl alcohol, and lint-free wipes are also important to keep stocked at the levels you will use in six months to a year.

“The actual inventory ideal for an agency will differ according to the conditions and how often parts need to be serviced,” adds Freddy. “Having spares available really helps you avoid deeper issues. It never hurts to have extras.”

If budget or space precludes keeping enough of these components on site to swap out parts in 10 percent of your fareboxes and vaults, a blanket PO can make it easier for maintenance staff to get the parts they need, when they need them, without going through red tape at their agency.

Having spare parts available allows maintenance staff to perform a quick service instead of taking hardware out of service for longer repair. Michael explains, “My daughter’s car didn’t come with a spare tire, so when she got a flat, she had to get it towed, which was a huge inconvenience. If she had a spare, she would have been able to swap it out for the damaged tire and drive on home on the spare.”

“The agencies that do preventive maintenance best go a step further and keep extra full modules on hand for a quick swap,” says Freddy. “For example, they could replace a TRiM unit and work on the TRiM they removed, then use the refurbished TRiM on the next farebox they service.”

Preventive maintenance training

Ongoing training is key to keeping hardware in top shape. Genfare can conduct in-person or remote training refreshers, conduct train-the-trainer courses for supervisors, or refer staff to online training videos and courses on the Customer Portal. Training and practice may be hard to fit into the schedule, but it will pay off in time and money savings, plus keep equipment collecting revenue.

“We understand that a lot of technicians have more than one job and there are only so many hours in the day,” says Freddy. “But it’s so important to give your technicians time to learn how to maintain the equipment, and to practice so they don’t forget how.”

Factors that influence preventive maintenance schedules

How long a component will last for between maintenance intervals varies by transit agency due to several factors. “Each agency should set their own thresholds for maintenance scheduling taking everything into consideration,” says Michael. “In general, if they need to service a bus engine more often, they will also need to service the farebox.”

Time and usage

Time and how often a component is used are the largest two factors. “It’s like the oil change in your car. They’ll tell you to come back in something like 3 months or 3,000 miles, whichever comes first.” says Freddy. “So, a bus route that prints a lot of transfer cards will need the TRiM serviced more often than a route that doesn’t – but even a seldom-used TRiM should be looked at after a certain length of time.”

The environment

After time and frequency of use, the climate your equipment operates in is the largest factor in how long certain components will last. This includes not just extreme temperatures, but factors including high or low humidity, salt air from a nearby ocean, particulates such as dust from area farms or deserts, and even diesel exhaust from the bus itself.

This can also mean maintenance needs to happen more often certain times of the year and less during others. Issues caused by the environment can include:

- Rubber belts and o-rings degraded by expansion and contraction of heat/cold cycles or melted under extreme heat.

- Lubricants stiffening in cold conditions or becoming gritty in dusty conditions.

- Controller boards corroding in humid conditions.

- Lubricants in outdoor vaults washing away from exposure to rain.

Dirty money and other junk

Any parts that handle coins or bills will get gunked up from the dirt that naturally builds up on cash. And that’s before you even consider things accidentally dropped into a coin cup such as pocket lint or paper clips. Additionally, sometimes riders will intentionally jam up fareboxes with chewing gum or liquids in an attempt to take the farebox out of revenue service so people can ride for free.

Preventive maintenance schedules

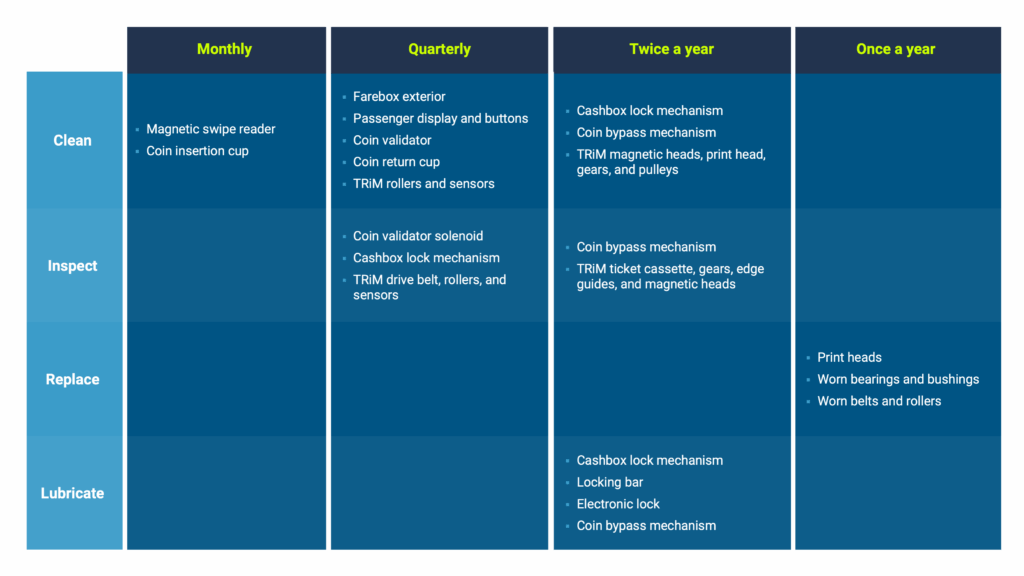

While the actual schedules will be influenced by the factors above and the fare collection equipment at each transit agency will vary, a maintenance schedule for the Fast Fare farebox might include tasks such as:

Ordering spares is faster and easier than ever

Just fill out Genfare’s new online form to request a quote. The Spares Request Form is easy to access from the login screen of the Customer Portal, even for customers without SSAs including portal accounts. You may also still contact Customer Care at 847-871-1231 or genfare.customercare@spx.com to request a quote.